Local Family-Owned Dairy Farms + Innovation

Nothing is better than fresh, pure milk products (milk, cheese and yogurt). We all know the slogan, “Milk—it does a body good,” but do you know why?

A Nutritional Powerhouse

First, dairy is an amazing source of protein, which is an important building-block of healthy muscle, skin, tissues, and blood. Several studies have shown that consuming milk products helps to maintain a healthy weight, most likely because of the protein. Milk is also a great source of calcium and vitamin D, which is important for building strong bones.

And here’s a fact not many people know milk has an abundance of electrolytes—it makes a great recovery sports drink for this reason!

Local Love

Most of the milk products you love come from local farms! For folks like myself in Central New York, we are lucky to have dozens of local, family-owned dairy farms. Team these local farmers up to create Cayuga Milk Ingredients and you get the freshest, purest milk products imaginable. Allow me the honor to introduce you to Cayuga Milk Ingredients.

Cow to Carton

Cayuga Milk Ingredients (CMI) is a 108,000 square-foot milk-processing facility in Auburn, NY. Each day, 2.3 million pounds of milk comes through this facility, all from within a 25-mile radius of the plant. A range of high-quality milk products are produced expediently—from the time that the cow is milked, the finished product manufactured at CMI can take less than nine hours to produce!

Earlier this month, I had the amazing opportunity to tour the Cayuga Milk Ingredients manufacturing plant. This company, near my hometown in Central New York is the ideal representation of how to produce fresh milk products.

As I arrived at the plant, a truck load of milk from a nearby dairy farm came in. The milk is tested for antibiotics and bacteria before it even enters the plant! This assures that the milk is wholesome and clean when it enters the facility, so that contamination is not possible. The importance of hygiene in this plant was very apparent—the facility was immaculate.

Cleanliness is King

Kevin Ellis, the CEO of Cayuga Milk Ingredients, an operation with 70 dedicated employees, gave me the tour. His and his employees’ attention to detail, cleanliness and high-quality products is off the charts! To ensure superior hygiene, employees and visitors wear booties, hair nets, a smock, and remove jewelry, and are required to wash their hands and change their booties no less than four times when they move deeper into the facility. Each increasing level of hygiene is strictly adhered to ensuring CMI’s products are of the highest quality.

Innovation

The way that the milk is processed is very innovative. Much of the production is computer-assisted to help reduce bacterial contamination and human error.

Both dried milk protein and liquid milk products are tested for quality assurance in this facility. The dried milk protein is held in the facility for 8-10 days with constant testing and retesting of microorganisms to assure that the finished product is as high-quality as possible.

At any given time, there are 2.5 million pounds of finished products, which include milk powders (used for…), and various milk protein powders. I am particularly intrigued by a product known as liquid ultra-filtered milk, which is produced with a high- pressure membrane system. This all-natural low-fat milk has double the amount of protein of standard skim milk and half the sugar! How cool is that?

I loved the approach of CMI’s CEO, Kevin Ellis: “Our employees are our most important resource. We’re dedicated to producing high-quality milk ingredients from our farmer owners’ high-quality milk, while simultaneously improving the dairy industry by raising the bar for high standards. We’re confident you’ll see that the finest products come from the finest ingredients. We promise to not only meet your expectations, but exceed them!”

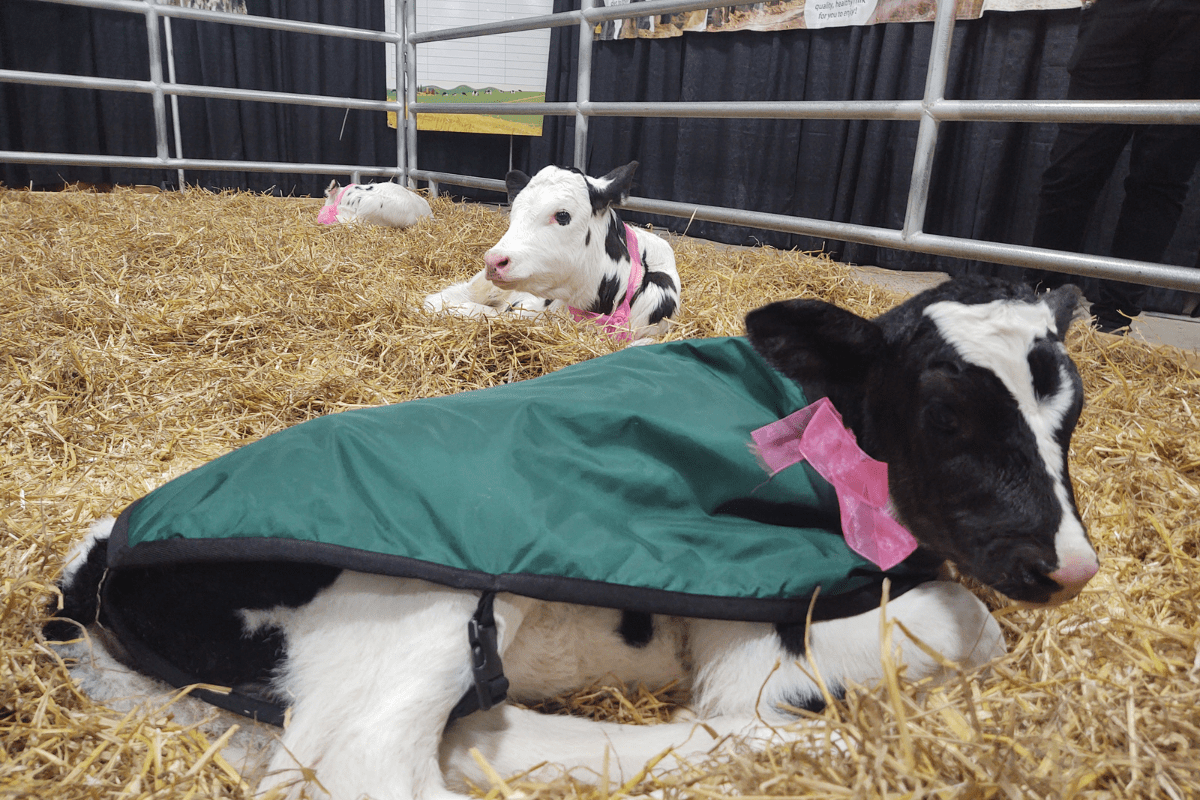

To me, it is awesome to know that ultra-high-quality, nutritious and pure milk products are being produced by CMI in such a way that family-owned farms, where cows are treated humanely are part of the process.